Digital Marketing, Digital Production, Science

3D Bioprinting: Revolutionizing Medicine and Tissue Engineering

João Marcos - Front End Developer

How Does 3D Bioprinting Work?

The bioprinting process generally involves three main steps:

1. Digital Modeling

It all starts with the creation of a three-dimensional

model based on medical imaging, such as CT scans

or MRIs. Specialized software converts these images

into a detailed model of the structure to be printed.

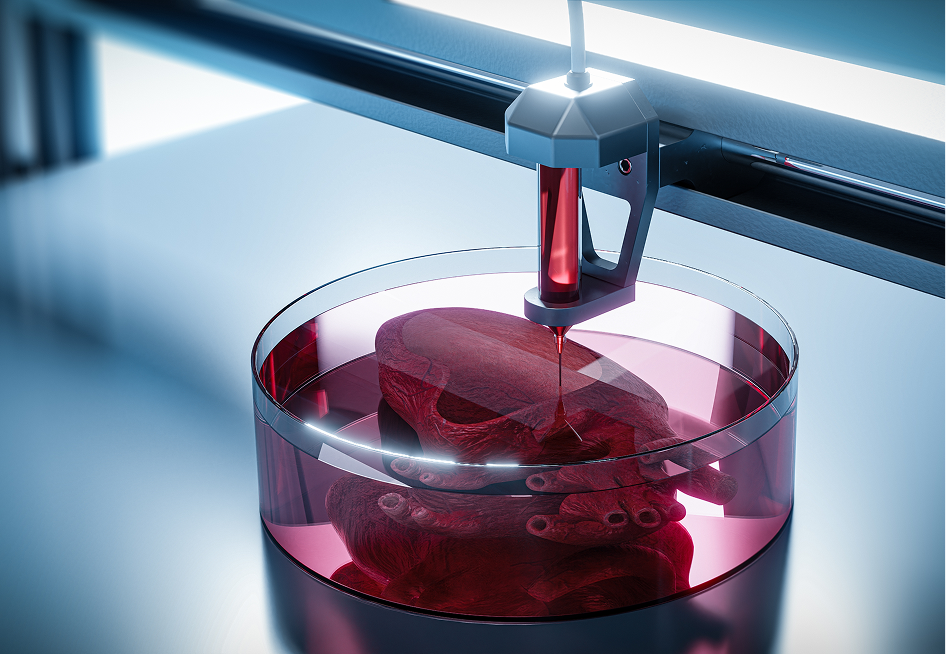

2. Bioink Preparation

The model is then sent to a 3D bioprinter, which

deposits layer upon layer of bio-ink. The most

common techniques involve inkjet, extrusion, and

laser, depending on the tissue type and the desired

precision.

3. Maturation and Development

After printing, the tissues undergo a cultivation

process in bioreactors, where they mature and gain

functionality, simulating conditions in the human

body.

Applications of 3D Bioprinting

The technology is already being used in various fields of science and medicine:

- Tissue Engineering: Production of living tissues such as skin, cartilage, blood vessels, and complex organs for transplants.

- Regenerative Medicine: Development of bioprinted tissues to repair or replace damaged organs.

- Pharmaceutical Testing: Using printed human tissues to test new drugs, reducing the need for animal testing.

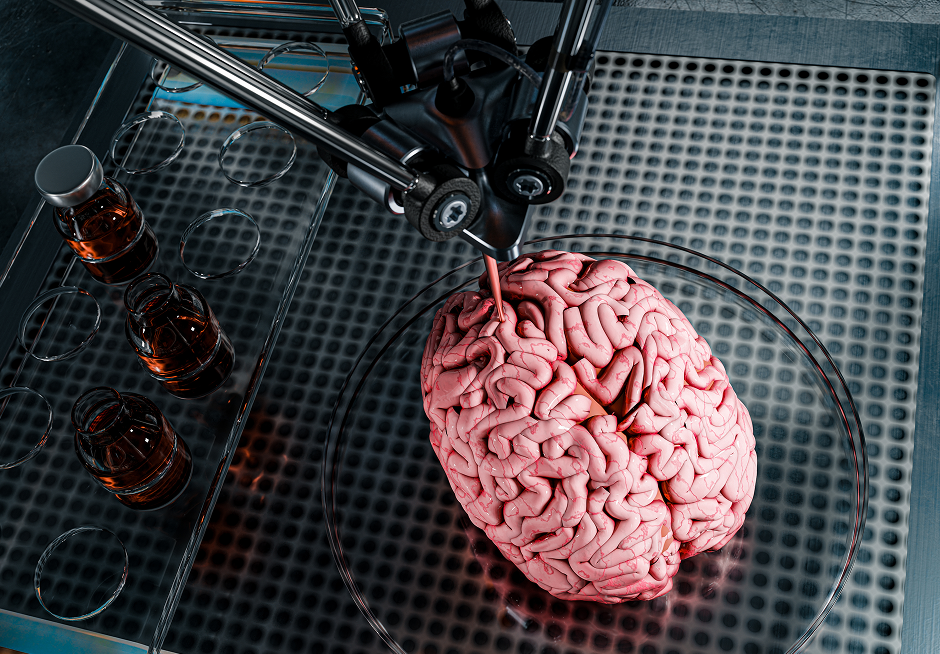

- Disease Models: Printing diseased tissues to study pathologies like cancer or neurodegenerative diseases.

Several biotech companies are already applying this technology with promising results. Organs such as the liver, kidney, and heart are being bioprinted for research purposes. In 2019, researchers at Tel Aviv University successfully bioprinted a small 3D heart with human tissue and blood vessels, marking a significant step toward creating fully functional organs. Countries like Sweden, Israel, and the US are leading the way in bioprinting research, advancing the development of novel tissue engineering solutions.

Challenges and Limitations

Despite the advances, there are still significant challenges:

- Cell Viability: Maintaining cell life during and after the printing process is one of the key technical hurdles to overcome.

- Structural Complexity: Reproducing functional organs requires complex vascular networks and intricate cellular interactions.

- Regulation: Bioprinted tissues and organs need to be useful in clinical treatments. They must pass strict regulations.

The Future Of 3D Bioprinting

As the technology evolves, 3D bioprinting is expected to become a viable and accessible solution to meet the global demand for transplants, accelerate medical research, and transform disease treatments. Growing investment from universities, startups, and major institutions indicates that this revolution is just beginning. For companies in the healthcare ecosystem — from research to the pharmaceutical industry — staying ahead of these innovations is crucial.

At Competitive Edge, we believe in the power of technology and communication to amplify the impact of these transformations. Connecting science, content, and strategy is part of our role as experts in healthcare communication.